With the global pet economy booming, the demand for scientific and nutritious pet food is surging. A pet food extruder for sale has become a core piece of equipment for pet food manufacturers, enabling the production of high-quality kibble, treats, and customized feed for dogs, cats, and even ornamental fish. Beyond pet food production, the diverse farming industry also requires specialized feed pellet machines for various animals and integrated feed production lines. Choosing the right equipment is key to seizing market opportunities and achieving profitable operations.

Core Advantages and Types of Pet Food Extruder for Sale

Pet food extruders are designed to meet the unique nutritional and texture requirements of different pets, with distinct advantages and diverse types to suit various production needs.

- Key Advantages: Adopting high-temperature and high-pressure extrusion technology, it can gelatinize starch and denature protein, improving feed digestibility by up to 30% . The extrusion process also kills harmful bacteria like salmonella, ensuring pet food safety. It supports customization of pellet sizes (1.0mm-16mm) and shapes, from small kibble for cats to large treats for dogs . Additionally, modern extruders feature precise temperature and pressure control, retaining the nutritional value of raw materials such as meat powder, grains, and vitamins.

- Main Types: Two primary types are available for different production goals—wet extruders and dry extruders . Wet extruders produce moist, palatable pet food with enhanced texture and higher nutritional retention, ideal for premium pet food lines. Dry extruders are more cost-effective and efficient, suitable for mass-producing dry kibble with lower operational costs and easier maintenance. Twin-screw extruders are also popular for their excellent mixing and shearing effects, ensuring uniform product quality .

Specialized Feed Pellet Machines for Other Animal Species

In addition to pet food extruders, different animal species have specific feed requirements, driving the development of various specialized equipment:

- Floating Fish Feed Extruder: Specialized in producing floating feed for tilapia, catfish, and ornamental fish. The 0.3-2TPH floating fish feed extruder machine uses extrusion technology to create porous pellets that float for 3-8 hours, reducing nutrient loss and water pollution . Suitable for aquaculture farms and aquatic feed manufacturers.

- Poultry Feed Pellet Machine: Tailored for chickens, ducks, and geese, it produces small-sized (2-4mm) high-hardness pellets. Adopting a high-speed rotating structure, it ensures uniform particle size and high pelleting rate, suitable for processing high-protein raw materials.For more details, please see:https://pelletmakingmachine.com/poultry-feed-pellet-machine/

- Ruminant Feed Pellet Machine: Designed for cattle, sheep, and goats, it has strong extrusion capacity to process high-fiber raw materials like straw and hay into granular feed. It improves roughage digestibility and can add molasses to enhance palatability.

Integrated Pet Food Production Line Matching Extruders

For commercial pet food factories, a single pet food extruder cannot meet large-volume and continuous production needs. An integrated production line matching the extruder ensures automated and efficient operation .

A complete pet food production line includes raw material cleaning and crushing equipment, mixing equipment, pet food extruder, drying and cooling equipment, and packaging equipment. The crushing equipment grinds raw materials into fine particles; the mixing equipment uniformly blends ingredients according to scientific formulas; after extrusion, the drying equipment reduces pellet moisture to 8-10% to extend shelf life; the cooling equipment ensures product stability; finally, the packaging equipment completes automatic weighing and packaging . Large-scale lines can also be equipped with automated batching systems and dust removal equipment to improve production precision and meet environmental standards.

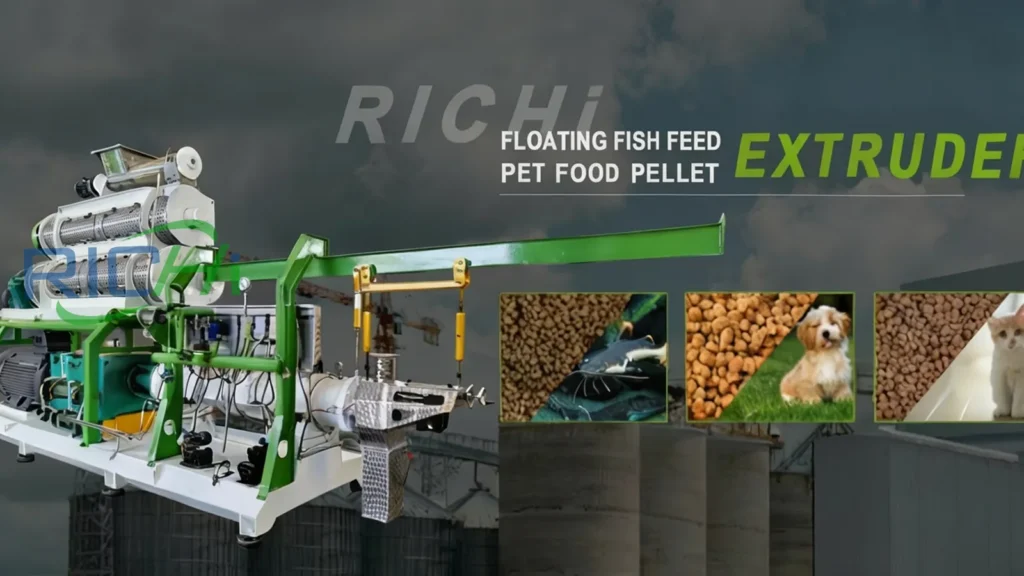

RICHI: Trusted Supplier of Pet Food Extruder for Sale

When selecting a pet food extruder for sale and matching production lines, choosing a reliable brand is crucial. RICHI, a professional feed machinery manufacturer with decades of experience, has won global recognition for high-quality products and comprehensive services .

RICHI’s pet food extruders adopt twin-screw structures with wear-resistant alloy screws and bushings, ensuring a long service life (screws >22,000 tons, bushings >50,000 tons) . They support customization of production capacity (0.5-20 tons per hour) and can process a wide range of feed types, including pet food, aquatic feed, and even livestock feed. RICHI also provides one-stop services, from pre-sales formula consulting and line design to on-site installation and after-sales maintenance. (more)

Key Considerations for Choosing Pet Food Extruder for Sale

To select the most suitable pet food extruder, consider the following factors:

- Production Scale: Small-scale businesses can choose compact dry extruders (20-50 kg/h), while large factories need industrial wet or twin-screw extruders (200-500 kg/h or more) .

- Pet Type and Product Demand: Select equipment with adjustable die specifications to match the pellet size and texture needs of dogs, cats, or other pets. For premium moist food, prioritize wet extruders; for dry kibble, dry extruders are more cost-effective .

- Equipment Quality and After-Sales: Prioritize extruders with food-grade stainless steel construction and high-quality core components. Choose suppliers like RICHI that offer timely technical support and spare parts supply .

- Automation Level: Evaluate based on labor resources—fully automated lines reduce manual intervention but require higher investment, while semi-automated models suit small-scale operations.

Conclusion: Invest in Pet Food Extruder for Sale for Business Success

A high-quality pet food extruder for sale is a strategic investment for entering the booming pet nutrition market. Matching it with specialized feed pellet makers for other animals and integrated production lines can expand business scope and improve overall efficiency.

By considering production scale, product demand, and equipment quality, and cooperating with a trusted brand like RICHI, you can obtain reliable equipment and professional solutions. This will help you produce high-quality pet food, reduce costs, and achieve sustainable profitability in the competitive pet economy.